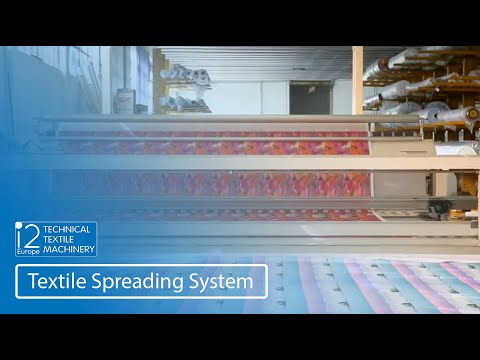

Spreading planning with steps. It’s provided with “tension free” spreading control for all fabric types from lycra to denim, from jersey to technical textiles by specific devices.

- Spreading speed with short acceleration and deceleration digitally adjustable

- Automatic electronic control of fabric tension

- Brushless main motors and service motors asynchronous type with variable speed

- 4 wheel-drive machine

- Cradle with alternative belts for rolls diameters of 50cm, up to 100cm as optional and max weight of 70kg

Unicont

The ultimate computerized spreading system. This machine allows to plan the spreading program directly from cad dept. to fully automate the cutting room planning, resulting in simple, yet accurate, greatly reduced working cycle.

The on-board computer provides just in time operating costs, fabric consumption, wastage and other vitally important data through the operating reporting system.

- Spreading planning is done automatically through the ISO format received directly from the CAD Room or other source

- Lays are programmed with up to 100 steps/colours

- Infrared laser defect pointer for the determination of fabric fault position in relation to the marker the software indicates the cutting position and overlapping point for fabric waste reduction

- Machine speed and acceleration adjustable digitally to suit each fabric type and special characteristics

- Automatic fabric threading

- Wireless connectivity

- Machine production completely integrated with ERP and/or WOM system.

To find our more about our Textile Spreading Systems please get in touch.