Some of our models incorporate a centre unwinding unit with shafts, whilst others allow the rolls to be placed on two rollers and surface unwound. The traction for unwinding, in both systems, is provided by the pull of the spreader trolley. We also have options for roll spreaders with large roll entry systems.

As with other machines, all machine parameters are controlled from a centre console via a touch screen display. This allows the operator to control the number of cuts, cutting length, cuts package, number of packages produced, but also the extended trolley speed, voltage, travel speed of the blade and speed of descent of the elevator table. This offers a great degree of precision and flexibility within production.

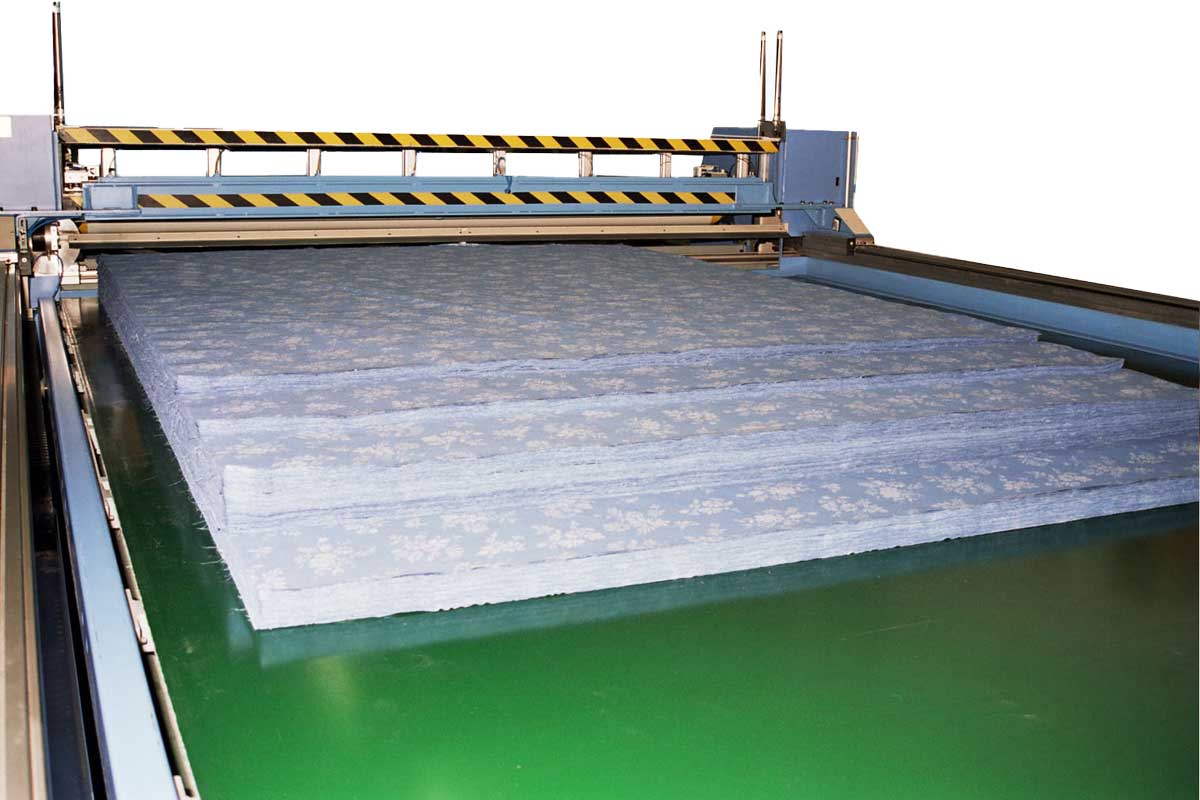

The lift table allows for stacking material up to 260 mm in thickness. It consists of two separate work areas: one for cutting, where the machine performs the spread, and the other for handling. Here, the operator can handle the material whilst the spreader cutter works in the other area. The product transport between the two areas is handled through PVC belts.

This machine is also able to operate from external feed systems, such as creels or simple trestles. This can increase the initial capacity of the machine, which is 3 or 4 rolls.

This spreading table is useful when manufacturing or handling:

- bedding, linens or clothing for hotels and the hospitality trade (or white sheets, pillows, pillow cases, comforters, duvets, quilts or blankets, rugs or blankets)

- mattresses (mattresses, mattress covers, mattress protectors)

- decoration (upholstery, sofa covers, curtains, blackouts)

- fashion (clothing and wear, footwear, interlining)

- bathroom linen (bath rugs, shower curtains, towels)

- technical fabrics, and aerospace and automotive requirements (turbine blades, fuselage, airbags, insulation, moulds)

- disposable hospital gowns

- banners, tarpaulins, tents and umbrellas.

- digital printing.

- table linen (tablecloths, napkins, table coverings)

- kitchen clothes (aprons, bibs, bread bags, tea towels)

- cleaning materials (cloths, mops, bags)

To discover more about our spreading table and cutter, please use our contact page and get in touch.