Fabric Inspection Machines

If you know that finding fault with something is good quality control practice, we are able to offer you an exciting range of fabric inspection machines, for use within the production or manufacturing of woven, knitted and non-woven fabrics and textiles.

The fabric inspection machines are often used to identify warp and weft faults in textile production but, with the addition of an automatic vision system, can also identify pattern mismatches, more complex fabric faults and other issues.

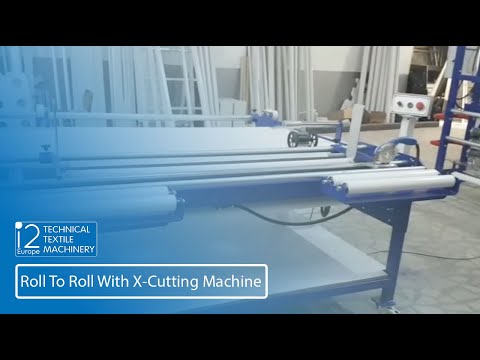

Our range offers you a choice of machine at different price levels, from simple re-winding tables with overhead or back-lighting, to fully specified inspection and batching machines. Typically, these all require one sole operator, who can carry out fabric inspection with ease, using the machine’s capacities.