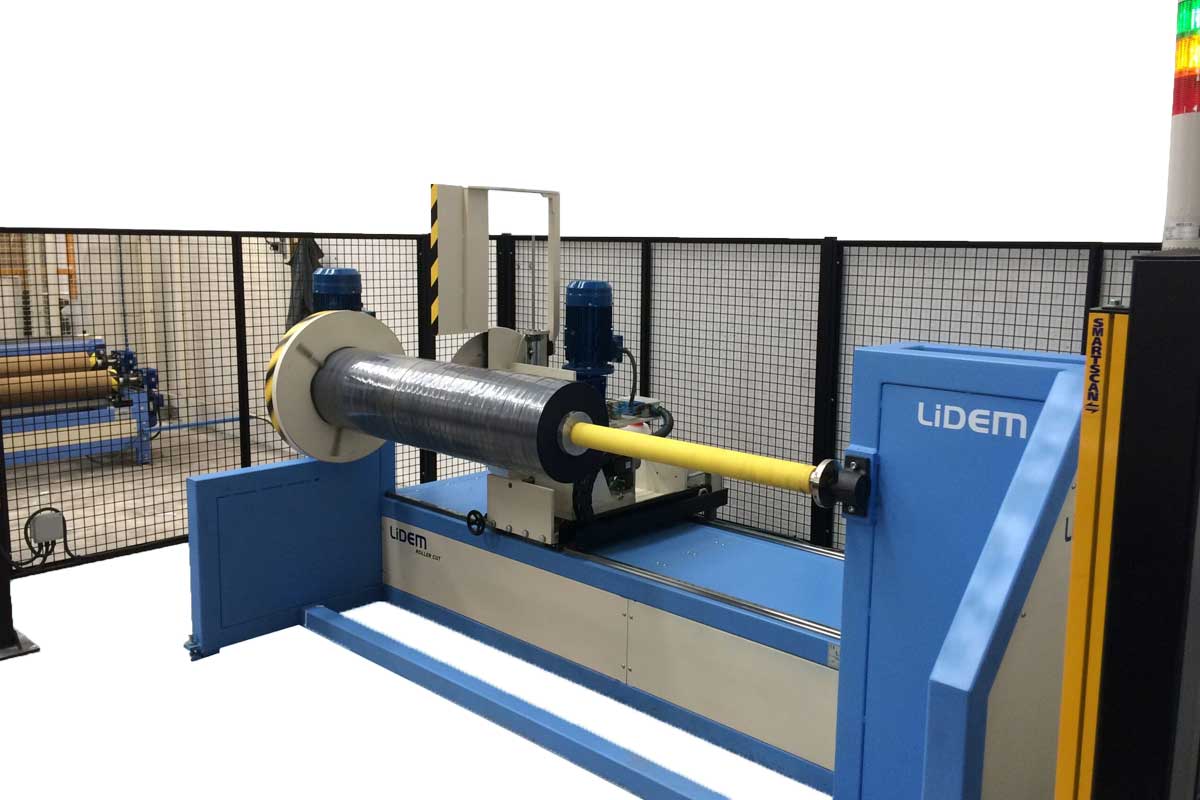

Automatic Roll Slitter

Numerically controlled automatic roll slitting machine for rolls with various diameter sizes, blade diameters. This machine has been designed with the utmost attention to safety features. The machine can process rolls of foam (PVC and polyurethane) even laminated with or without adhesives, rubber, plastic films, material for thermal and acoustic insulation of the buildings, glass and carbon fibres, roofing materials etc.