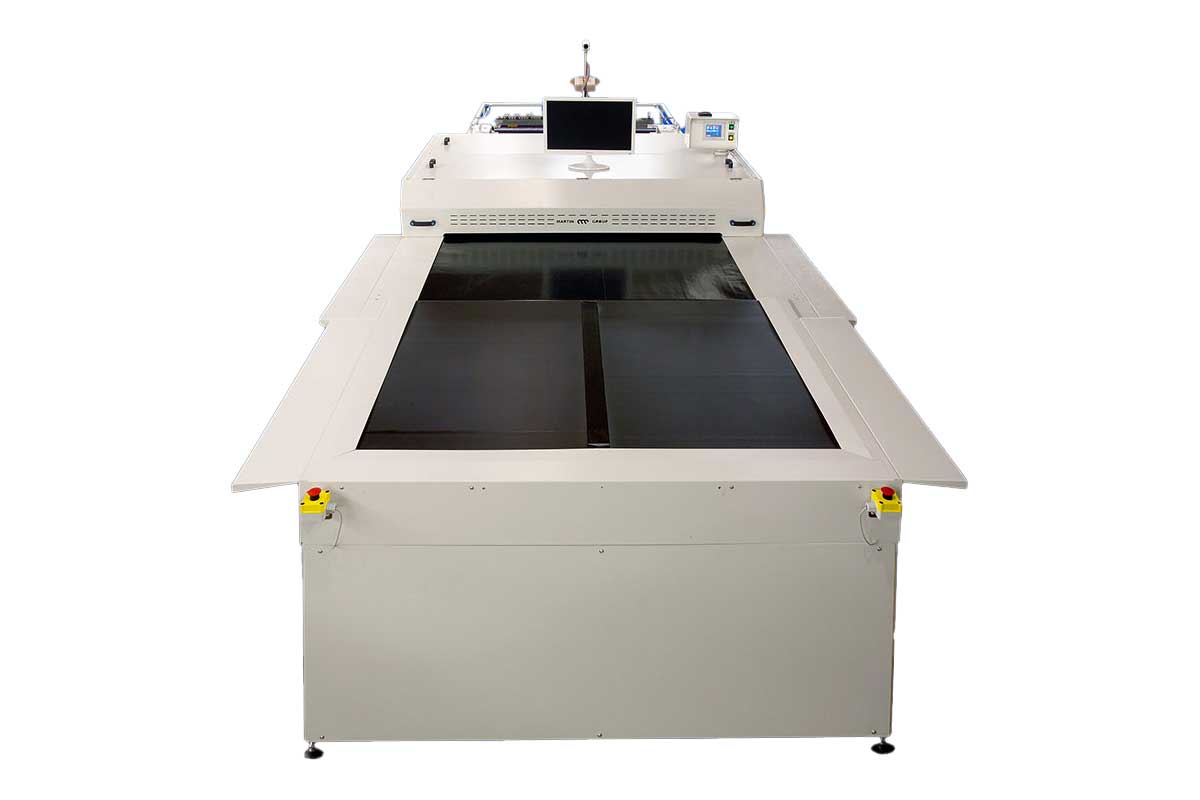

This machine is a real ally when it comes to fabric bonding and lamination of piece products in an easy-to-handle way. Its modular design means the OT series flatbed laminator can be equipped with stackers, various feeding stations and a return belt device, along with many other in-feed, stacking and winding options.

The infeed belt allows the products to be manually aligned before bonding. The option to add multi-roll driven unwind rolls, with individual edge guiding, allows rolled products to be perfectly aligned and fed, without any of the tension on a single product that could cause a distortion of the finished article.

Heating and pressure application with the OT series fabric bonder

The heating area in the OT series is 1400 mm long, to ensure the best and most accurate heating are for the fusing of the materials, using a fusing average speed of 6m/min. The heating zone configuration is usefully separated, so the top and bottom of the machine are controlled independently. This allows for pre-heating within the first section with its top heating plate, to start the melting of adhesive. The longer, bottom heating plate allows the products to be bonded by gravity alone, before the pressure system kicks in at the end, to apply added pressure. The curved-plate heating system is, however, designed to allow smooth fusing without pressure. The ability to apply up to 60N/sq.cm (up to 6Bar) of direct pressure, therefore, helps the bonding process only where necessary.

Notes

Where rotary or flatbed bonding may not be appropriate, as might be the case in PPE production, there is another solution within our range, so please speak to us about our ultrasonic bonding solutions.

Different products require different parameters to achieve the correct result, so a combination of heat, time and pressure for one product may not suit a different product. Our broad experience in this field allows us to advise you on the most suitable combinations for treated, woven, non-woven, mono and bi stretch materials, so please take the opportunity to tap into our knowledge, by getting in touch with us, via our ‘contact us’ page.

Sizes & Width

The Open Top machine is available in the following widths:

700, 1000, 1240, 1400, 1600, 1800. It may also be available in wider widths, so contact us for more details.

Control System

The control for the OT is handled by means of a touchscreen. This covers all standard functions as follows:

- on/off

- per zone temperature setting

- pressure on/off and actual pressure setting

- belt speed indication and control in m/min and showing the dwell time

- reverse function

- auto cooldown

- alarm indications with suggested solutions

- programmable memory buttons for individual products with all functionality saved

- standard touch screen or LAN connection option

Optional Equipment

- different combinations of pressure rollers

- manual roll feed frame – 1,2 or 3 rolls

- motorised roll feed frame with edge guiding – 1,2 or 3 rolls

- manual roll winding

- motorised roll winding with edge guiding

- feed table variations (size and number of persons)

- stacking units

- return feed belts, for limited space locations

- anti-static

- entry side cross cutter

- cooling fan, chiller options