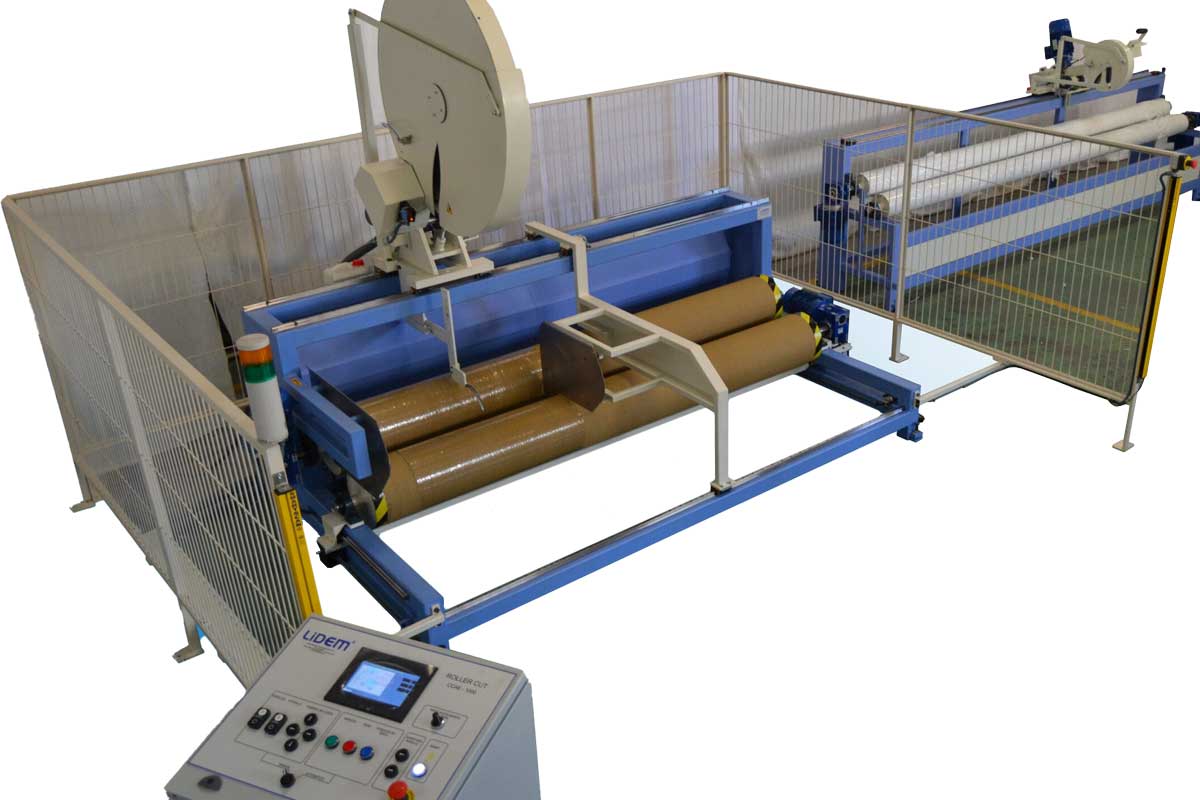

The cradle roller has adjustable spacing which allows perfect support for the material, whether you are preparing to cut from the smallest of diameter rolls, or the largest.

A dual-speed, in-built cutting head, offers a fast speed for when approaching the roll and another speed for scheduled cutting. The cutting head starts its lateral movement immediately after the blade has released the roll, maximising available production time and reducing preparation time and displacement. Easy sharpening is also achieved, whenever required.

Another handy feature is the integrated blade lubrication system, which allows for the easy cutting of fuses or fusible materials, such as nonwoven (TST and TNT nonwoven fabric), as well as polypropylene, polyester and plastics.

This automatic roll cutting solution is suitable for use with:

- bedding, white linen or clothing for hotels (white sheets, pillows, pillow cases, eiderdowns, duvets, bedspreads or blankets, rugs or blankets)

- mattresses (mattresses, mattress covers, mattress protectors)

- decoration (upholstery, sofa covers, curtains, blackouts)

- fashion items (clothing and wear, footwear, interlining)

- intimate apparel (underwear, lingerie, pyjamas, nightgowns)

- ribbons, borders and bias

- bathroom linen (bath rugs, shower curtains, towels, bathing suits, swimsuits, bikinis)

- applications technical fabrics, aerospace and automotive (turbine blades, fuselage, air-bags, insulation, moulds)

- disposable hospital gowns

- banners, tarpaulins, tents and umbrellas.

- digital printing.

- table linen (tablecloths, napkins, table coverings)

- kitchen clothes and items (aprons, bibs, bread bags, tea towels)

- Cleaning material (cloths, mops, bags)

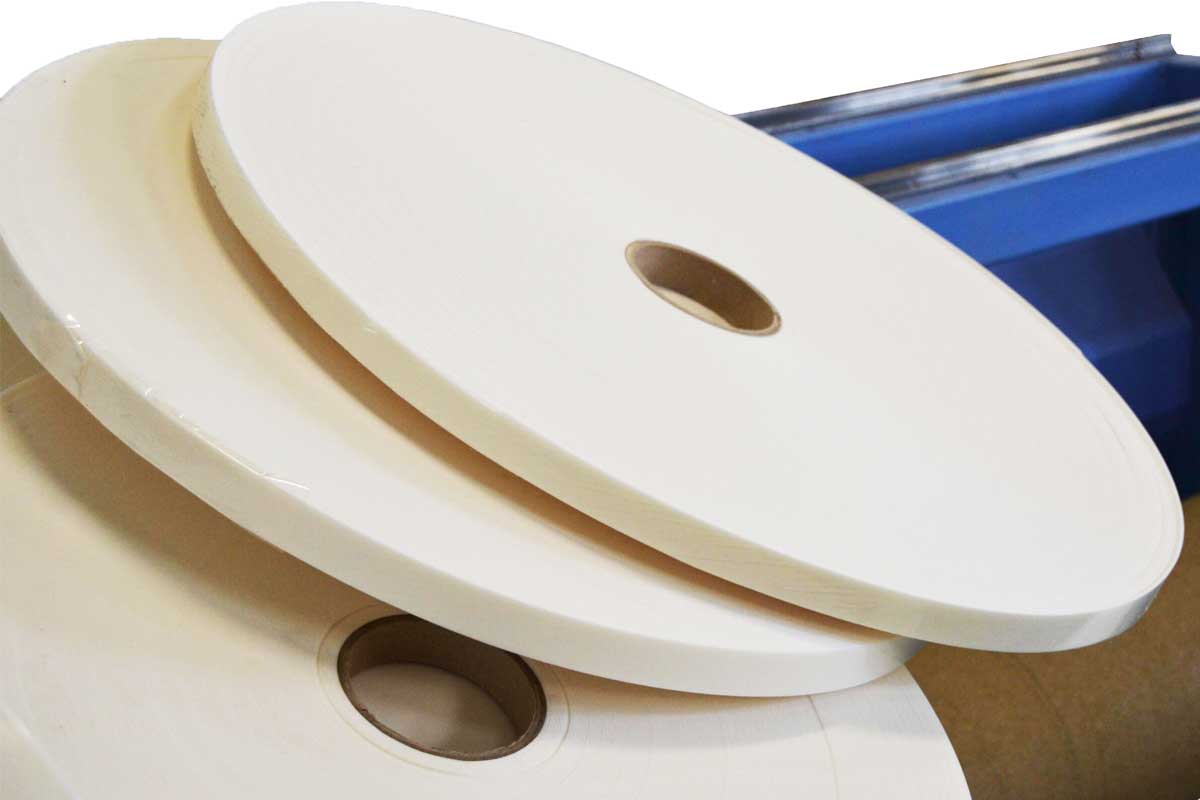

Our versatile RollCut machines can cut a wide range of materials in different diameter and length. Examples can be found here.

To find out more about our automatic roll cutting equipment, please visit our ‘contact us’ page and get in touch by the means that best suits you.