What is a coating?

A coating is a covering applied to the surface of an object, usually referred to as the substrate. The purpose of applying the finish may be decorative, functional, or both.

The coating may be an all-over finish, completely covering the substrate – something you might well find if it is an anti-microbial coating – or it may only cover parts of the substrate.

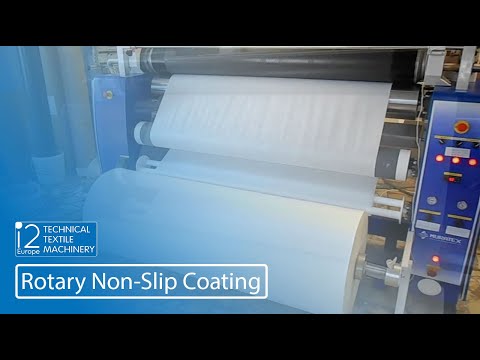

Functional coatings can change the surface properties of the substrate, to assist with a certain process. This could include applying a pre-coating to a fabric before printing on to its surface, to make the fabric non-slip during printing.

The coating or finish applied to the fabric is typically applied in a way that controls the thickness. A number of different processes can be used to achieve this.

When it comes to partial coating, equal precision is required to determine exactly where the finish needs to be applied. A number of these coating processes, which pinpoint an area for a finish’s application are for printing purposes. For instance, a non-slip area might be required on a garment, so that a client logo can be printed on to it.

Fabric and Materials’ Coating Methodologies

In general, for a thin uniform coating layer to be applied, the application must be done at low or moderate viscosities. In many cases this low viscosity is achieved by dissolving or dispersing the desired product in a liquid such as water or a solvent, but this then necessitates the subsequent removal of the liquid by, for instance, a drying process.

In contrast, hot-melt coating achieves this low-to-moderate viscosity by melting the desired material before applying it to the substrate. The substrate and coated layer are then cooled, often by passing them over a chilled roller. There is no liquid to remove, so the process is, in principle, much faster than when using water or solvent-based equivalents.

Bonding, Roll to Roll Coating and Converting

Many industrial coating processes involve the application or bonding of a thin film of functional material to a substrate, such as paper, fabric, film or foil. If the substrate starts and ends the process wound up in a roll, the process may be termed ‘roll-to-roll’ coating or converting.

Machines for Coating, Bonding and Converting

Our coating and bonding machines offer the advantages of being a compact build with an optimised footprint – ideal where floor space is at a premium. They operate in flexible ways and are backed by a highly competitive pricing structure, to work within clients’ budgets. By working with us, you will be assured of top-quality guidance with regard to the machine that will best suit your coating brief.

Sizes & Widths

Available for web widths of up to 5.0m.

Technology Types

We can provide many types of technology such as:

- Air over knife

- Knife over air

- Rotary

- Foulard

- Single-sided

- Double-sided

- Dip tank

Drying Systems

Drying processes often work alongside and in synergy with many coating machines, and there are machines which are able to deliver the drying functionality that makes life simpler. Here at i2Europe, we have a full range of drying systems, which can be tailored to suit your specific requirements. Please just ask us for help with these drying machines, as well as details of our coating and anti-microbial coating options.

Want to chat through the options? Please visit our ‘contact us’ page for more information.